一 . Before installing the drill, it shall comply with the provisions of "the installation of the drill and the assembly of the drill shall be carried out in accordance with the factory instructions, and the erection or placement of the drill frame shall be carried out by skilled professionals".

二. The installation site of the drilling rig should be smooth and rammed, which can bear the working pressure of the machine; When the foundation is poor, steel plate protection should be added under the drill.

三. The crane matched with the drill shall be selected according to the height and lifting weight required when forming piles. When the rig is connected with the crane, the connection of all parts should be firm and reliable. The hydraulic tubing and cable between the drill and the power plant shall be connected according to the factory instructions.

四. The voltage of the lighting power supply introduced into the unit should not exceed 36V.

五. Appearance inspection shall be carried out before operation and shall meet the following requirements:

1. The appearance of each part of the drill is good, and the connecting bolts are not loose;

2, fuel oil, lubricating oil, hydraulic oil, cooling water, etc., meet the regulations, no leakage phenomenon;

3, each wire rope without damage and corrosion, the connection is correct;

4. There is no abnormal phenomenon in the clutch and brake of each winch, and the hydraulic device works effectively;

5. There is no obvious deformation and damage inside the casing and pouring pipe, and it is not bonded by concrete.

六.The in ternal combustion ENGINE can only be started after the inspection is confirmed to be correct, and the idling speed is gradually accelerated to the rated speed, and the rig is aligned according to the specified pile position, and the horizontal and horizontal direction of the rig is achieved through the test adjustment before the operation.

七.The crew should monitor the indicator data of each instrument, follow the operation sound, should immediately stop processing if abnormal exist.

八. After the first casing is put into the soil, the perpendicularity of the casing should be adjusted at any time. When the casing is below 5m, it shall not be forced to correct deviation.

九. In the process of operation, when the main engine is found to sink on the ground and hydraulic support, it should be stopped immediately. After using 30mm thick steel plate or subgrade box to expand the bearing surface and reduce the ground stress, the operation can be continued.

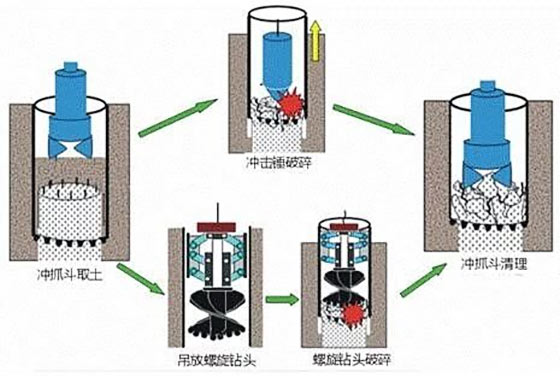

十. In the excavation of the soil layer in the sleeve, when hard soil rock and weathered rock hard layer is encountered, the hammer grab shall not be used to impact the hard layer. The cross chisel shall be used to effectively break the hard layer before continuing to excavate.

十一. When the hammer grab is used to excavate the soil, a bell mouth to protect the casing joint should be installed on the casing.

十二. When the casing is connected, the joint bolt should be tightened symmetrically according to the torque specified in the factory instruction. When the joint bolt is removed, it should be washed immediately and immersed in oil.

十三. When lifting casing, special tools should be used to lift it, and it is not allowed to hang it directly in the threaded hole with clasp, or to use other lifting methods that damage the thread of casing.

十四. In the process of digging, the casing should be kept swinging. When it is found that the casing can not swing, the hydraulic cylinder should be pulled out to lift the casing, and then the crane to help pull out, until the part of the casing can swing.

十五. When pouring concrete, the drilling rig operation should be closely coordinated with the pouring operation. Pipes should be properly arranged according to the hole depth and pile length, and the casing should be concentric with the pouring pipe. When the pouring pipe is buried between 2-4M of concrete, pipes should be pulled out and removed simultaneously, and the quality of the pouring pile should be ensured.

十六. After operation, the concrete and sediment on the surface of the body, hammer grab and casing should be removed on the spot, the frame should be put back to the walking place, and the unit should be transferred to a safe place 十六、作业后,应就地清除机体、锤式抓斗及套管等外表的混凝土和泥沙,将机架放回行走的原位,将机组转移至安全场所。